Our facilities

Glass Processing Facilities

Our Glass department is providing now a full Range of glass fabrication and related works; we have well equipped machineries, we have our own Tempering plant, Lamination plant. We have a warehouse with huge capacity of glass storage and we mainly dealing directly with international and national glass manufactures &suppliers like saint gobain, Guardian glass, AGC glass, intraco, emirate glass… we fabricates glass into Double glazing,framelessglass,laminated,polished,beveledglass, design sandblasting, all mirror related works and so much more.. This all items served for your building with full Quality and attractive price.

optimax 6133 ES cutting line is manufactured by HEGLA Germany one of the largest and advanced glass machinery manufacturers in the world, the machine can cut rectangular and shaped coated and uncoated glass from 3mm to 19mm thickness with double head cutting and edge deletion head (10mm- 20mm). Moreover, laminated glass can be cut on the same machine from 4mm to 22 mm thickness. Loading the glass to cutting table is automatically controlled by a 14 rack Gantry.

Maximum Size handling: 6100 x 3300.

Cutting Capacity: 1200 SQM per 9 Hour Shift.

Fully automatic glass cutting table for float and special glasses with a supplementary grinding unit which allows coating removal. Straight cuts can be grinded and cut simultaneously in a single work step. Low cycle times with maximum quality are the result. Shapes and even digitized shapes can be cut without any difficulty.

• Simultaneous grinding and cutting of straight cuts

• Optimum cut quality with minimum tolerances of +/- 0.15 mm

• Grinding 360° in one step

• Fixed stripping brush at the bottom

• Second oil feed

• Automatic cutting pressure control

Glass Insulating line is manufactured by FOREL

A fully automatic vertical IG Line Manufactured by FOREL a leading Italian company in manufacturing glass processing machinery, this line is consisting of:

• Forel 2250 Vertical automatic washing and drying machine with automatic Lowe and soft coated detector, maximum size of glass 3000 x 2500 and from 3 to 52 mm glass thickness.

• Aluminium spacers frame mounting station.

• Forel AP-2250 Coupling press station, maximum size of 3000 x 2500 and 52 mm thickness, applicable for rectangular, shapes and offset processing, and triple glazing units.• Forel PBN 632 Automatic profile bender applicable for rectangular and shapes spacers from 6mm to 32 mm.

• Forel DFN 632 Automatic desiccant filler applicable for rectangular and shapes spacers from 6mm to 32 mm.

• Forel MB 7501 Butyl rubber extruder for rectangular and shaper spacers from 6mm to 32 mm.

• Forel SA 1425 Automatic sealing robot head applicable for rectangular and

shapes panels and automatic sealing of Shuco profiles and triple glazing units,

maximum thickness up to 52 mm.

• Forel manual Automatic pumps (2 units) for special sizes and shapes processing.

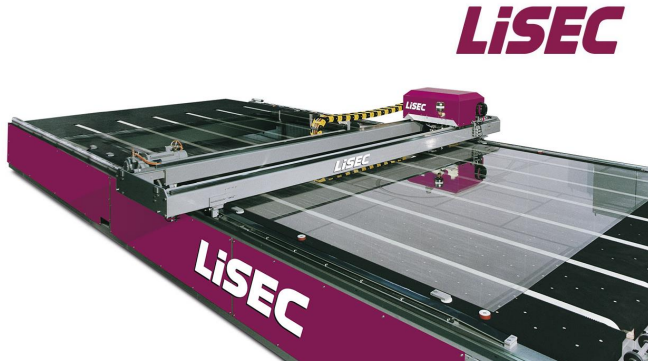

The LISEC insulating machine is an integrated and continuous solution for fast and uncomplicated processing of the most common glasses and dimensions. The line is aimed especially at complete processing of interior glasses such as doors, side pieces or dividers. Splitting the processing steps allows a significantly higher output; the individual machines have been built to fit the required dimensions and requirements.

The Split Fin sets new standards in user friendliness and ease of maintenance, since all important mechanical components are easily accessible and if possible, located in the dry area.

UNIGLASS Extra 2400 x 4800 Flat Tempering Line

A horizontal flat glass tempering furnace Manufactured by UNI- GLASS Finland, with a maximum size of 2400 x 4800, which can process all types of uncoated and all temperable coated glass, form 4mm to 19 mm thickness and heat strengthening from 3mm to 12mm thickness. With this advance version of UGT, we can reach up to 19 cycles of 6mm clear tempered glass per 1 Hr. Moreover, this furnace is attached to a hi-tech horizontal washing and drying machine manufactured by Triulzi Italy with automatic Low-e and special coated glass detector, and automatic adjustable up to 35mm glass thickness.

MOUNTAIN MT-GP Series Flat Glass Tempering Furnaces

Product Description: MT-GP series flat glass tempering furnace is mainly used to produce top-grade flat tempered glass for furniture, household appliance.

Technical Characteristics: MT-GP Series Flat Glass Tempering Furnaces.

Fully Automatic Flat Laminating Line, the latest technology in the lamination industry, from Shenzhen Handong Glass Machinery, Model JC2550J-HD, with the following features:

• High Speed Washing and Drying.

• Fully Insulated PVB film Positioning and Inspection Station.

• Fully Insulated Assembling and Trimming Station.

• Fully Insulated PVB Storage Room.

• Fully Automated Preheating and Pre-pressing Zones.

• Fully Automated Main Heating and Pressing Zones.

• Centralized Control System.

• Maximum Glass Size: 2500 x 6000mm

• Maximum Glass Size: 420 x 250mm

• Range of Unit Thickness: 6mm to 80mm

IPRO ITGS 2600- Automatic sandblasting machine with 3 auto guns and 1 manual, applicable for sandblasting processing up to 50mm thickness and a maximum height of 2300 mm.

Bevelloni VT 1250 manufactured by Z. Double head with handling glass up to maximum hole diameter of 220mm.

• Drilling machine Bevelloni Italy with applicable for 50mm thickness

Bevelloni polishing Gemy 9 C manufactured by Z. Bevelloni Italy, an automatic vertical straight line edging with 9 cup wheels for flat and arise edges, and 1 cylindrical wheel to process corners cutting of the glass, applicable for glass processing from 3 to 40 mm with a working speed up to 5m/min.

Bevelloni beveling B75 CN manufactured by Z. Bevelloni Italy, and automatic numerical straight line Beveling machine with 7 Cup wheels, applicable for glass thickness from 3 to 20 mm and the maximum width of the bevel is 55mm, with double or triple beveling.